“Green hydrogen” is a trending buzzword you may have heard on the news, but what is it, and what is it used for?

The potential of green hydrogen

Green hydrogen is a promising energy source that, when properly produced, results in little to no planet-warming greenhouse gas emissions.

But not all hydrogen is created equal.

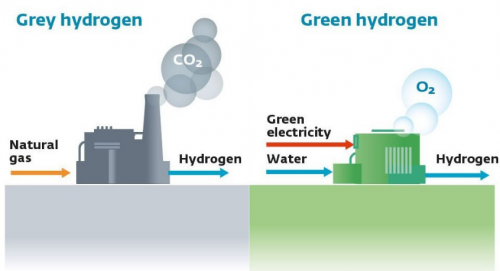

While hydrogen itself does not release carbon, most of the world’s hydrogen is currently made using fossil fuels like coal and natural gas. Burning fossil fuels releases excess carbon dioxide, methane, and other greenhouse gases into the atmosphere. These greenhouse gases act as a heat-trapping blanket around our planet, warming our atmosphere and oceans at unprecedented rates.

For now, most hydrogen is produced through a process called steam methane reforming, in which natural gas is heated with steam to produce a mixture of carbon dioxide and hydrogen. Because this method results in greenhouse gas emissions, this form of hydrogen is often dubbed “gray” hydrogen.

To reduce our greenhouse gas emissions and slow the planet’s atmospheric warming, energy sources that result in little to no emissions, like green hydrogen, have become increasingly important.

Green hydrogen differs from gray hydrogen because it is produced by 100% renewable energy sources like wind and solar. This is done through a process known as electrolysis – which only requires electricity to split water into hydrogen and oxygen. This reaction takes place in a machine called an electrolyzer. The process is emissions-free, as long as the electricity used is generated from a green energy source, like solar.

Jonathan Scheffe, an associate professor in the department of mechanical and aerospace engineering at the University of Florida, likened green hydrogen to a Swiss army knife.

Once green hydrogen is produced, it can be easily stored and has many uses. It can be stored in existing gas pipelines to help power household appliances, like water heaters, and can be used with fuel cells to power things like electric vehicles and devices. Green hydrogen is also showing promise in the fertilizer industry.

“There’s a lot of interest in hydrogen because it’s so versatile,” said Scheffe.

But, currently, solutions for effective storing of hydrogen are needed, Scheffe added.

The cost of hydrogen

Although it has great potential for reducing emissions in various industries, producing green hydrogen is costly. In the United States, green hydrogen is around three times more expensive than gray hydrogen.

In 2021, Biden administration launched the Hydrogen Shot initiative, which aims to reduce the cost of clean hydrogen by 80% to $1 per 1 kilogram in one decade compared to today’s cost of $5 to $6 per kilogram. Additionally, the Inflation Reduction Act (IRA) established a tax credit of $3 per kilogram of zero- or low-carbon hydrogen made, potentially making green hydrogen cost-competitive to its natural gas-derived counterpart, gray hydrogen.

The battle to define green hydrogen

When talking about “green” vs. “gray” hydrogen, the terms are not so black and white.

The U.S. Treasury Department is currently weighing opinions on how to write rules to ensure the hydrogen produced with the IRA’s tax credits is, in fact, green. Without clear requirements, the Inflation Reduction Act tax credit leaves room for fossil fuel companies and utility companies to make their own interpretations.

At the heart of this debate is how “green” will be defined and whether clean electricity that powers the process of electrolysis has to be accounted for on an hourly or annual basis.

Climate scientists, environmental groups, and energy analysts are asking the Treasury Department to require hourly matching. In order for hydrogen to be considered green under hourly matching, the electrolysis process would need to be powered by renewable energy that was happening within the same hour. Under this scenario, when clean energy isn’t readily available, the electrolyzer would need to stop running temporarily.

This video shows how hourly matching is generally used for renewable resources like solar and wind energy connected to the electrical grid.

On the flip side is annual matching. With annual matching, an electrolyzer would default to fossil-fuel based electricity when clean energy is not regionally available, like when the wind isn’t blowing or the sun isn’t shining. To make up for this, utility companies would purchase an equal amount of clean electricity on an annual basis from anywhere in the country or send the same amount of wind or solar energy back to the network when supply is higher than demand.

This could allow hydrogen producers to get credit for generating solar somewhere else and apply the tax credit to the hydrogen, even though it was generated with fossil fuels, explained Alissa Schafer, a researcher at the Energy and Policy Institute, a pro-clean energy utility watchdog group.

“With annual matching, you’re still using a lot of fossil fuel, but you’re getting credit for having renewable energy somewhere within the same year,” Schafer said. She emphasized that with billions of dollars on the line, imposing stricter rules like hourly matching is important to ensuring a truly green future for hydrogen.

NextEra Energy, the parent company to Florida Power & Light, which just began operations on its first green hydrogen facility last month, is advocating for the annual matching requirement.

“Requiring that time matching be…hourly, would potentially devastate the economics of clean hydrogen production,” they wrote in their comments to the Treasury Department.

Proponents of annual matching argue that the more hours per day an electrolyzer is in operation, the cheaper the green hydrogen will become.

Researchers at Princeton University identified two other accounting standards in addition to hourly matching to ensure that energy used from the electrical grid to power electrolysis is produced in a clean way. Together with hourly matching, they make up the “three pillars” for a better tax credit, according to the researchers:

- Additionality – The electricity for electrolysis has to come from newly built sources of clean electricity. The more energy we use, the more clean energy we need. If new renewable facilities are not built to keep up, the increase in demand will still be supplemented by fossil fuels.

- Regional deliverability – Clean electricity has to be close enough to be physically delivered to the electrolysis facility.

Fueling the future

Hydrogen has many attractive applications for reducing global greenhouse gas emissions, but it is expensive to produce and limited by existing infrastructure.

“We are addicted to using a lot of energy in this country, so we need powerful sources and hydrogen has a potential to be that source. It’s just really critical that we get it right,” said Schafer.